-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

CNC (computer numerical controlled) machining is a widely used manufacturing process that uses automated, high-speed cutting tools to form designs. At KUNFENG, we posses a superior capability to meet large diameter part challenges efficiently, and without sacrificing quality. With our state-of-the-art equipment, and fully integrated engineering and production control system, KUNFENG has what is takes to meet the most complex and demanding requirements.

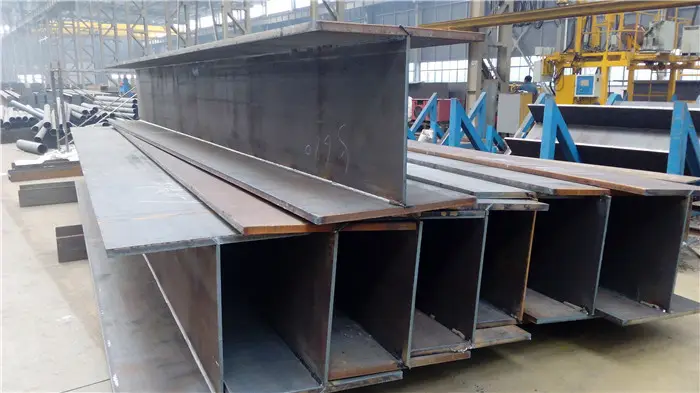

Before gantry machining, Kunfeng offers cutting and welding services, as well as CNC milling, boring, turning, honing, etc. Our gantry machining center can provide our customers with processing length from 10 to 22 meters, and diameter from Φ160 to 250, making it ideal for large-scale projects such as custom ship bodies, pressure vessels, and box structures.

Materials Used

• Steel

• Ductile Iron

• Stainless Steel

• Aluminum

• Gray Iron

Machined Parts in Applications

Large diameter components produced by KUNFENG cover a broad range of industries and applications.

• OEM Parts

• Cylinders

• Clutch Housings

• Precision Shafts

• Pulleys

• Rollers

• Spindles

• Hydraulic Parts

• Threaded Parts

Industries we serve

• Aerospace

• Construction & Mining

• Agricultural

• Defense

KUNFENG Steel has grown to become the preferred supplier of metal parts for businesses, engineers and inventors around the world. We offer manufacturing services including gantry CNC milling, metal welding & cutting, metal materials parts and more than 100 materials. Our highly qualitified machines can make custom simple or complex designs. Our CNC service offers metals and shipping options to meet you at the perfect price and product development stage.

KUNFENG Steel guarantees the quality of your parts with our ISO 9001 certified quality management system, and options to add inspections, hardware traceability, material certifications. We accept technical drawings and have support teams to ensure you to get your CNC machined parts at quality and on time.