-

Call Now ! +86 177 2978 0576

Call Now ! +86 177 2978 0576 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

In today's world of cutting-edge technology and miniaturized components, metal micro machining has emerged as a crucial process for industries seeking unparalleled precision and accuracy. In this

In today's world of cutting-edge technology and miniaturized components, metal micro machining has emerged as a crucial process for industries seeking unparalleled precision and accuracy. In this article, we delve into the realm of micro machining, exploring its definition,signification and diverse applications. Discover how this advanced technique can revolutionize manufacturing and meet the demands of industries requiring intricate components at microscopic scales.

What is Micro Machining?

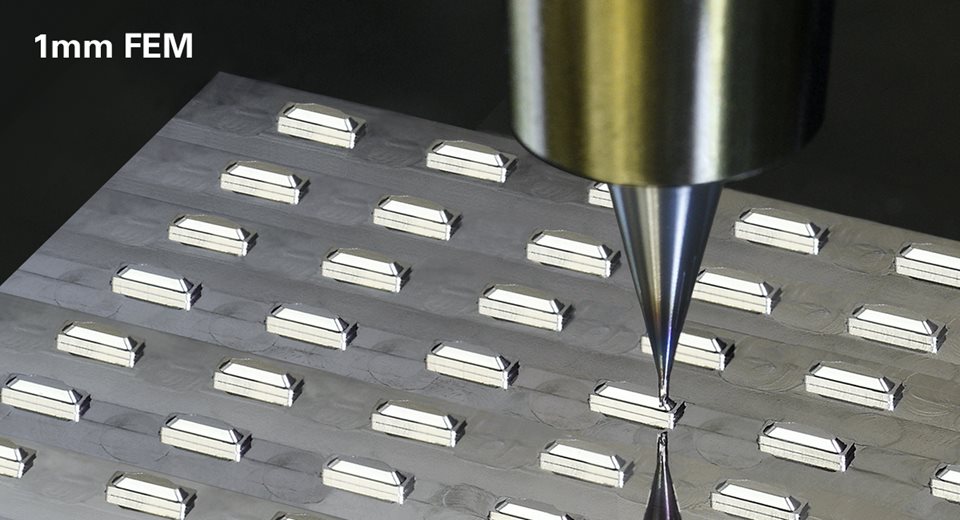

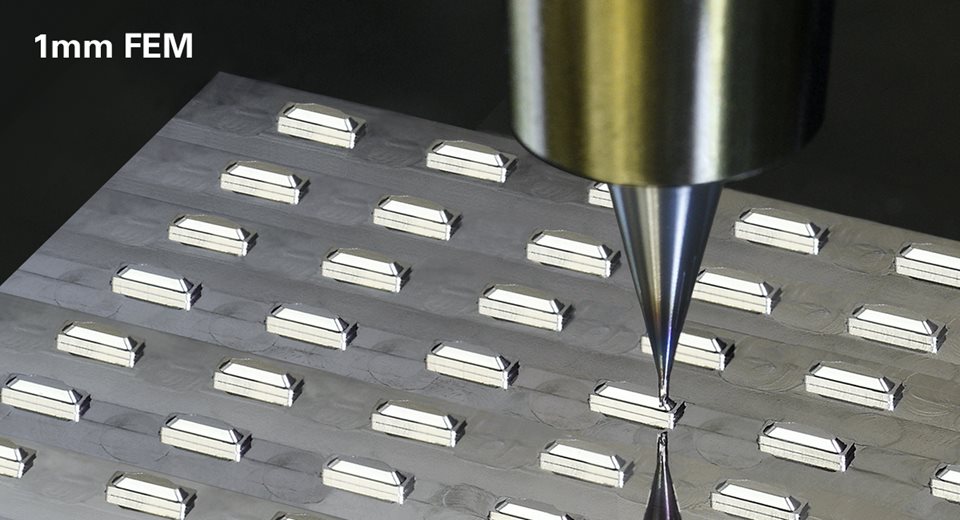

Micro machining is a specialized manufacturing process that involves the production of tiny, intricate components with sub-millimeter dimensions. It utilizes advanced machining techniques, such as high-precision CNC (Computer Numerical Control) machinery, to fabricate precise features, intricate patterns, and complex geometries.

In addition, micro machining involves cutting, drilling, milling, and finishing operations performed on a range of materials, including metals, carbon steel, alloys, and stainless steel, etc. KUNFENG Steel offers the precision tolerance ranging from 1-25mm diameters. And the specific tolerance can be discussed with the customer, given the part material, size and geometry.

Why is Micro Machining Needed?

Versatility: Micro machining is needed to meet the growing demand for miniaturization in industries such as electronics, medical devices, aerospace, automotive, and telecommunications.

Precision: 5 axis CNC machining enable the production of components with intricate internal structures, precise surface features. Micro machining offers advantages such as exceptional precision ranging from 1-25mm diameters, the ability to create complex geometries, and cost-effectiveness.

CNC micro machining enables the creation of microelectromechanical systems (MEMS), microfluidic devices, optical components, micro sensors, and more, facilitating advancements in areas like healthcare, telecommunications, and consumer electronics.

Application of Micro Machining

Micro machining finds application in diverse industries, each with unique requirements for precision and miniaturization.

• In the electronics industry, CNC micro machining is used to fabricate microchips, printed circuit boards (PCBs), and minuature connectors.

• In the medical industry, CNC micro machining helps production in surgical implants, microfluidic devices, and biomedical sensors.

• In the aerospace and automotive industries, CNC precision machining is great for manufacturing turbine blades, fuel injectors, and precision mechanical components.

Conclusion

Micro machining has become an indispensable process for industries embracing miniaturization and precision engineering. Micro machining enables the production of intricate components with unparalleled accuracy and reliability.

KUNFENG Steel constantly improve our custom CNC turning lathe services and machining, turning, milling technology to produce the most suitable and satisfied CNC precision parts and components. From electronics to healthcare and beyond, this cutting-edge process paves the way for innovation, advancements, and the realization of complex designs on a microscopic scale.