-

Call Now ! +86 177 2978 0576

Call Now ! +86 177 2978 0576 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

Introduction In the realm of advanced manufacturing, 5-axis machining has emerged as a game-changer, revolutionizing the production of complex components with unparalleled precision and versatility.

Introduction

In the realm of advanced manufacturing, 5-axis machining has emerged as a game-changer, revolutionizing the production of complex components with unparalleled precision and versatility. In this article, we explore the working principle, distinctive features, and diverse applications of 5-axis machining. Discover how this cutting-edge technology is transforming industries and unlocking new possibilities in the world of precision engineering.

What is 5 Axis Machining

Compared with 3 axis machines, a single 5 axis machine with the latest technology can typically do the same work with significantly shorter manufacturing times than multiple 3 axis machines.

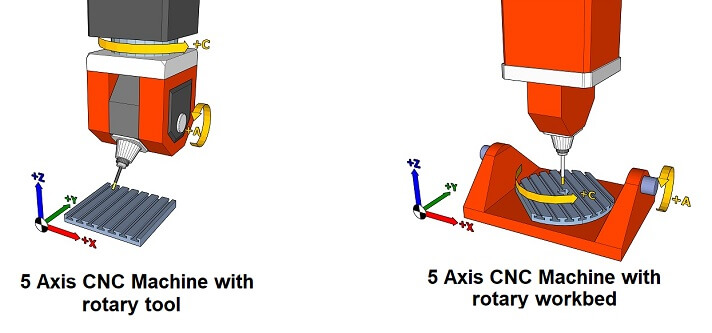

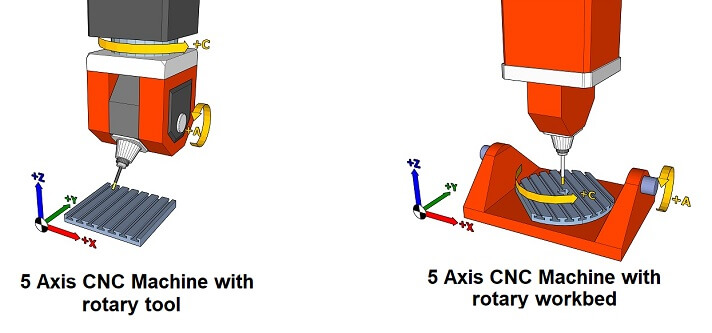

5-axis machining is a sophisticated CNC (Computer Numerical Control) milling technique that allows for simultaneous movement of the cutting tool along five different axes: X, Y, Z, as well as rotation around the X and Y axes. By employing a multi-axis setup, 5-axis machines can access various angles and orientations, enabling the fabrication of intricate geometries and complex contours in a single operation. This dynamic movement capability empowers manufacturers to achieve superior precision and efficiency in the production of highly complex components.

If you've never seen 5-axis in motion, try this: " Hold an object from the bottom, out in front of you. Point a pen down vertically above the object. While tipping the object left and right, forward and backward (the A and B-axes), simultaneously move the pen up, down, side to side, in and out (the X, Y, and Z-axes). "

Distinctive Features

The key feature of 5 axis machining lies in its ability to perform complex operations with a single setup, eliminating the need for multiple machine repositioning and reducing production time. The simultaneous movement along multiple axes enables the creation of intricate shapes, undercuts, and compound angles that are challenging to achieve using traditional 3 axis or 4 axis machining. With 5 axis machining, manufacturers can achieve exceptional surface finishes, tight tolerances, and intricate designs, pushing the boundaries of precision engineering.

Applications

The applications of 5-axis machining span a wide range of industries, including aerospace, automotive, medical, and mold making.

• Aerospace: 5-axis machines are used to fabricate critical components such as turbine blades, aircraft structural parts, and complex engine components.

• Automotive: The automotive industry benefits from 5-axis machining for manufacturing intricate molds, tooling, and prototype parts.

• Medical device manufacturing: 5-axis machines enable the production of customized implants, surgical instruments, and orthopedic components with precise geometries.

• Mold and die industry: 5-axis machining finds application in the mold and die industry, where it can create complex mold cavities, intricate cores, and precise details.

Conclusion

5-axis machining allows for the creation of intricate components with accuracy and versatility that was not possible before. This cutting-edge technology uses simultaneous movement along multiple axes, which has opened up new horizons for industries seeking complex geometries, efficient production processes, and superior surface finishes. The potential of 5-axis machining is immense, and it can unlock new possibilities in advanced manufacturing.