-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

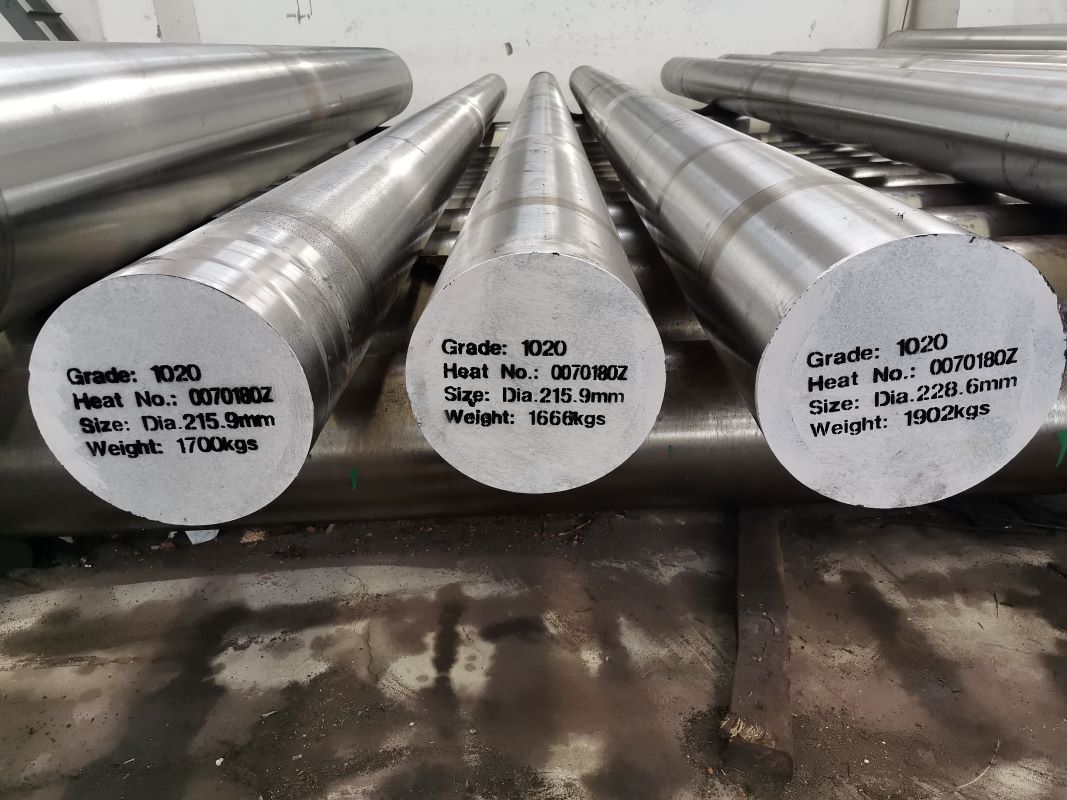

1020 steel round bar is widely used in medium and heavy machinery industry, such as forging or suppression of rod, shackle, leverage, sleeve, fixture, etc. 1020 belongs to high quality low carbon steel, cold extrusion, carburizing and hardening steel. The low steel strength, toughness, plasticity and weldability are good. Tensile strength of 253-500 mpa, the elongation is 24% or higher.

Details:

Standard: DIN 7527-6,EN 10204, EN 10228-3,EN 10250,N10083,SEW 550

Delivery Condition: Hot forged +Normalized+ Rough turned

Q/T: Quench+ Temper Annealing

Steelmaking Process: electric furnace + LF refining furnace + argon protection casting + VD vacuum degassing furnace ingot (bottom gating)

Diameter: 5mm-1200mm ,the forged round bar is from 80mm-1200mm:

Length: 1000-12000mm

Inspecting: SEP1921 CLASS C/C,D/D,E/E

1020 forged steel round bar Tolerance: OD: 0/+3.0mm Length: 0/+20.0mm Straightness: 3mm/1000mm

Chemical analysis -% by mass*

Grade | C | Si | Mn | P | S | Cr | Ni | Cu | Mo |

max | max | max | max. | max. | max | max | max | max | |

1020 | 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | 0.025 | 0.025 | 0.60-0.90 | 1.25-1.65 | 0.25 | 0.15-0.25 |

1020 steel round bar Merchanical Propertites

Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation in 100-150 mm(%) | Reduction in Area | Hardness |

1020 | ≥380 | ≥210 | ≥25 | ≥50 | ≤111HB |

KUNFENG can offer 1020 forged and hot rolled round bar in carbon, alloy, stainless steel material, Our Company through quality, environment, occupational health and safety management system, etc. Products have passed the ISO9001:2000 quality management system certification, China CCS, South Korea KR, Italy RINA, Japan NK, France BV, the United States ABS, Russia RS, Lloyd's LR, Germany Lloyd's GL classification society certification.