-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

What is 3 Axis Machining?3 Axis machining refers to a subtractive manufacturing process that use CNC machine automatically complete the task by using a tool too cut along three axes. For example, CNC

What is 3 Axis Machining?

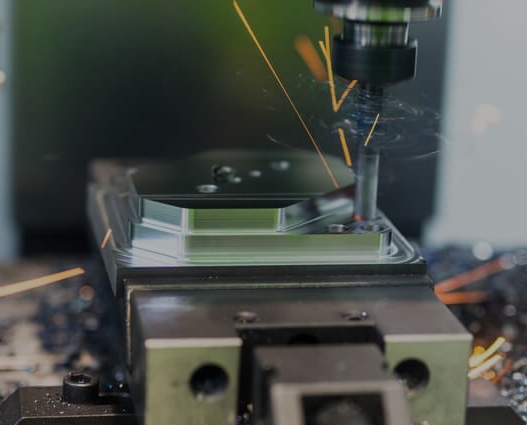

3 Axis machining refers to a subtractive manufacturing process that use CNC machine automatically complete the task by using a tool too cut along three axes. For example, CNC milling and CNC turning.

How does 3 Axis Machining Work?

3 axis machining implies that the workpiece remains in the same position while the cutting tool operates along the XYZ plane to trim away material. Compared with 4 axis machining and 5 axis machining, it only cut along three axes, so it isn’t ideal for deep or narrow parts because it's limited on effectively reaching deep or narrow cavities on the material and may become more labor-intensive.

Application of 3 Axis Machining

3 axis CNC milling machine is excellent for producing most simple parts and geometries. For example, automatic/interactive operation, milling slots, drilling holes, cutting sharp edges.

In addition to the 3 axis CNC machining, 4 Axis and 5 Axis machining are welcomed the world. The more axis ensures the more accurate positioning.

TYPES OF CNC MACHINES

3 Axis – X, Y, and Z axes

4 Axis – X, Y, Z, and A axes

5 Axis – X, Y, and Z axes and two out A, B, and C axes

AXES MOVEMENTS

X axis – left to right

Y axis – front to back

Z axis – up and down

A axis – 180° rotation around the X axis

B axis – 180° rotation around the Y axis

C axis - 180° rotation around the Z axis

Where to Start?

Are you ready to locate a 3 axis machining facility and get to work? Start by identifying what you need, what cutting tool work best.

With over 10 years machining experience, KUNFENG Steel leverages state-of-the-art machinery and a highly skilled workforce to deliver precision parts machining services that surpass industry standards. By employing gantry CNC machine, such as turning, milling, boring, we keep manufacturing intricate parts with tight tolerances, enabling agricultural machining to operate flawlessly even under demanding conditions. At KUNFENG Steel, we deliver business solutions the gap between strategy and execution for global organizations of all sizes. For more information, fill out our form to contact us, and we will be in touch!