-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

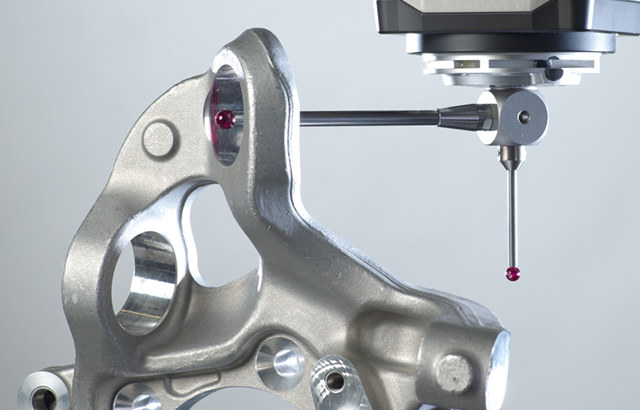

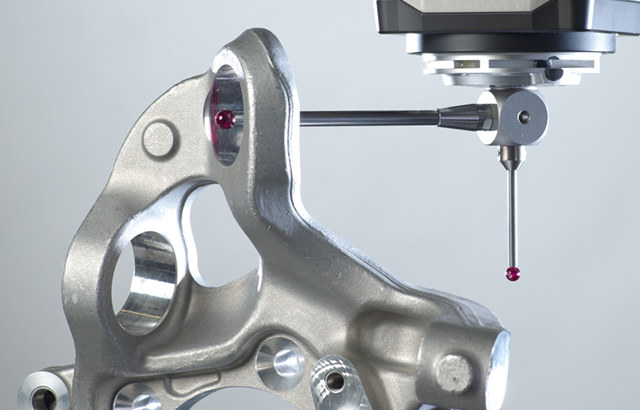

Precision machining is essential in the medical industry, particularly for fabricating parts that require extremely tight tolerances. This process, known as medical machining, utilizes advanced techni

Precision machining is essential in the medical industry, particularly for fabricating parts that require extremely tight tolerances. This process, known as medical machining, utilizes advanced technical resources to create a variety of medical components, ranging from surgical tools to monitoring devices. With the help of medical machining, the medical indsutry can meet anda exceed the demands for precise and reliable equipment.

Why CNC machining can be applied for medical parts?

CNC machining is ideal for medical parts due to its precision, versatility with different materials, customization capabilities, efficiency, and compliance with regulatory standards. It enables the production of complex, customized parts with tight tolerances, making it suitable for applications like surgical instruments, implants, and prosthetics. CNC machining also allows for rapid prototyping and cost-effective production, while ensuring adherence to strict quality and safety regulations in the medical industry.

Medical Machining Application

We are capable of machining a diverse range of materials including but not limited to Titanium, Stainless Steels, Beryllium, Chromium, Bronze, Brass, Hastelloy, Chrome Alloys, Copper, Invar, Manganese, Molybdenum, Ceramics, Acetal, PEEK, ABS, PVC, UHMW, Inconel, Monel, Peek, Kovar, Silver, Silicone, Nylons, Polymers, and Composites. We also offer the service of silver and gold plating wherever requested.

Medical components are applied in the following situations:

• Electronic Medical

• Micro machining

• Cardiovascular Devices

• Orthopedic Devices

• Surgical Instrumentation

• Implants

KUNFENG Steel provides custom machining services for various industries, from marine to medical and aerospace. We are capable of producing both large and small precision components per your request.

CNC machining is ideal for medical parts due to its precision, versatility with different materials, customization capabilities, efficiency, and compliance with regulatory standards. It enables the production of complex, customized parts with tight tolerances, making it suitable for applications like surgical instruments, implants, and prosthetics. CNC machining also allows for rapid prototyping and cost-effective production, while ensuring adherence to strict quality and safety regulations in the medical industry.