-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

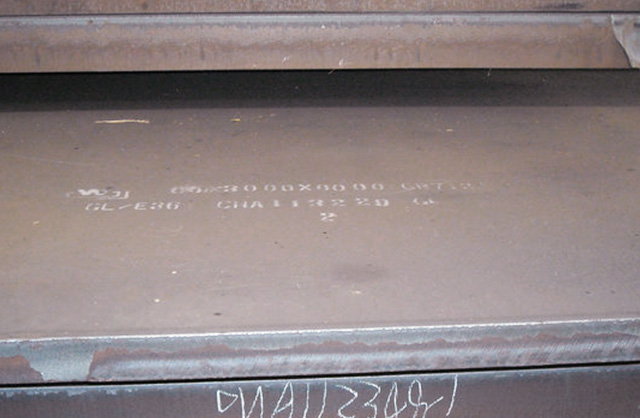

GB/T 3077 35CrMnSiA alloy steel plate is a low-alloy ultra-high-strength steel, GB/T 3077 35CrMnSiA alloy steel plate has a good overall mechanical properties after heat treatment, high strength, sufficient toughness, hardenability, weldability (preheating before welding), processing formability are good, but the corrosion resistance and Low oxidation resistance, GB/T 3077 35CrMnSiA alloy steel plate generally used after low temperature tempering or isothermal quenching.

GB/T 3077 35CrMnSiA alloy steel plate is used to manufacture medium-speed, heavy-duty, high-strength, high-toughness parts and high-strength components. It is mainly used for manufacturing high-load, high-speed various important parts, such as gears, shafts, clutches, sprockets, grinding wheel shafts, bushings, bolts, nuts, etc. GB/T 3077 35CrMnSiA alloy steel plate is also used to make parts that are wear-resistant, have low working temperatures, and change loads. Welded components, such as blades, valve plates, and non-corrosive pipe tubes of high-pressure blowers

35CrMnSiA Chemical Composition | |||||

Grade | The Element Max (%) | ||||

C | Si | Mn | P | S | |

35CrMnSiA | 0.32~0.39 | 1.10~1.40 | 0.80~1.10 | 0.025 | 0.025 |

| Grade | 35CrMnSiA Mechanical Property | |||

Thickness | Yield | Tensile | HB | |

35CrMnSiA | mm | Min Mpa | Mpa | HB |

6-50 |

|

|

| |

50-200 |

| |||

(1) Quenching: 950°C for the first time, 890°C for the second time, oil cooling; 230°C for tempering, air cooling and oil cooling;

(2) 880°C for austempering at 280-310°C.

For heat treatment (normalizing, annealing or high temperature tempering) or for delivery without heat treatment, the delivery status shall be stated in the contract. Welcome to contact us if you are looking for the suppliers of GB/T 3077 35CrMnSiA alloy steel plate. we will try our best to reply you at the first time