-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

WHAT IS CNC BORING?Gantry CNC boring, also known as computer numerical control boring, is a machining process used to create cylindrical holes with tight tolerances and precise dimensions in metal or

WHAT IS CNC BORING?

Gantry CNC boring, also known as computer numerical control boring, is a machining process used to create cylindrical holes with tight tolerances and precise dimensions in metal or other materials. It is a highly accurate method of boring that uses automated machinery controlled by computer programs to produce precise cuts and shapes.

HOW DOES CNC BORING WORK?

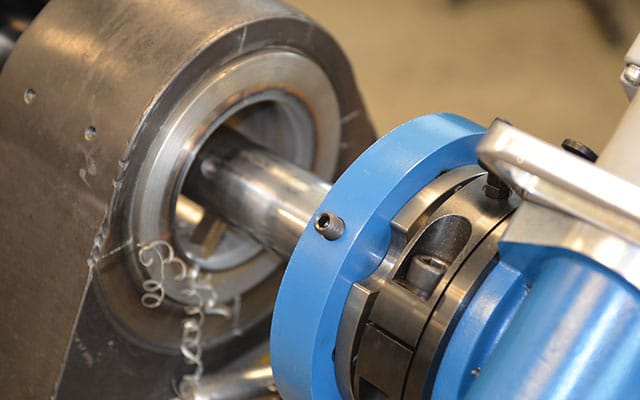

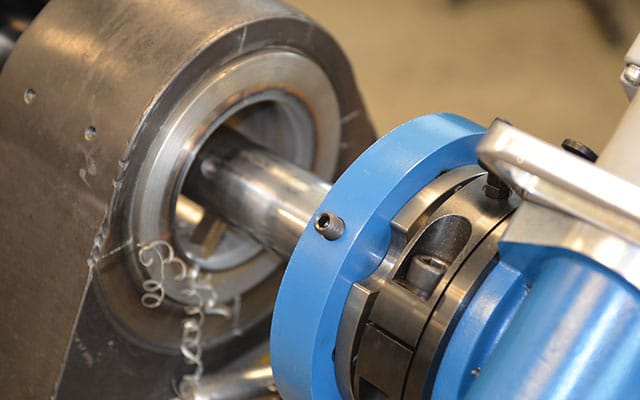

The process of CNC boring begins with a workpiece, which is typically a large block of metal or other material. The workpiece is mounted onto a specialized machine tool, such as a horizontal boring mill or vertical boring mill.

With the help of a boring machine, a little size hole with an accuracy of less than 32mm can be accomplished. A boring machine's head will slowly move into the hole that was pre-drilled or cast, and then gradually scrape away at the outer walls in a controlled fashion. In turn, this results in a larger hole.

WHERE IS BORING USED?

CNC boring is also commonly used for drilling deep holes, creating precise bores for bearings and other mechanical components, and producing threaded holes. The following is a wide variety of industries:

• Aerospace

In the aerospace industry, CNC boring is used to create complex engine parts and other components that require high levels of precision.

• Automotive

In the automotive industry, it is used to produce engine blocks, transmission cases, and other critical components.

• Medical

In the medical industry, it is used to produce orthopedic implants, surgical instruments, and other medical devices.

• Manufacturing

• Tool and die

... ...

Overall, CNC boring is a highly accurate and efficient machining process that is used in a wide variety of industries and applications. Its ability to produce precise holes and cavities in large, complex workpieces makes it an essential tool for modern manufacturing.

KUNFENG Steel is proud of offer a host of machine service, including steel cutting and welding, CNC milling, boring, turning and threading. One of the many service we're proud to offer is our boring, of which we perform many different kinds.

Visit our page to learn more about the size parts we can drill for you.