-

Call Now ! +86 13390692151

Call Now ! +86 13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes computerized controls and specialized machines to create complex shapes and designs with high precision

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes computerized controls and specialized machines to create complex shapes and designs with high precision. This process has revolutionized the manufacturing industry, allowing for the creation of intricate and detailed parts and components that would be difficult or impossible to produce with traditional methods.

There are several types of CNC machining services available, each with its own unique features and applications. Some of the most common types of CNC machining services include:

1. Milling: Milling is a type of CNC machining that uses a rotating cutting tool to remove material from a workpiece. This process can be used to create a wide range of shapes and designs, including complex curves and contours.

2. Turning: Turning is a type of CNC machining that involves rotating a workpiece while a cutting tool removes material to create a cylindrical shape. This process is commonly used to create parts such as shafts, bolts, and nuts.

3. Drilling: Drilling is a type of CNC machining that involves creating holes in a workpiece. This process can be used to create holes of various sizes and shapes, and can be used to create precision holes for components such as bearings and fasteners.

4. Grinding: Grinding is a type of CNC machining that involves using an abrasive wheel to remove material from a workpiece. This process is commonly used to create precise finishes on parts and components.

One of the key features of CNC machining is its high level of precision. CNC machines can be programmed to create parts with tolerances as small as a few microns, ensuring that each part is identical to the next. Additionally, CNC machining allows for the creation of complex shapes and designs that would be difficult or impossible to produce with traditional methods.

INDUSTRIES & APPLICATIONS

1. Aerospace: CNC steel machining is used extensively in the aerospace industry to create parts and components for aircraft and spacecraft. These parts must be highly precise and durable, and CNC machining is ideal for meeting these requirements.

2. Automotive: CNC machining is used in the automotive industry to create parts for engines, transmissions, and other components. These parts must be able to withstand high temperatures and pressures, and CNC machining is ideal for creating parts that can meet these requirements.

3. Medical: CNC machining is used in the medical industry to create precision parts and components for medical devices and instruments. These parts must be highly precise and sterile, and CNC machining is ideal for meeting these requirements.

4. Electronics: CNC machining is used in the electronics industry to create parts and components for electronic devices such as smartphones, computers, and televisions. These parts must be highly precise and durable, and CNC machining is ideal for creating parts that can meet these requirements.

In conclusion, CNC metal machining is a versatile and precise manufacturing process that has revolutionized the manufacturing industry. With its ability to create complex shapes and designs with high precision, CNC metal machining is used in a wide range of applications across various industries. Whether you are in the aerospace, automotive, medical, or electronics industry, CNC machining can help you create the parts and components you need to succeed.

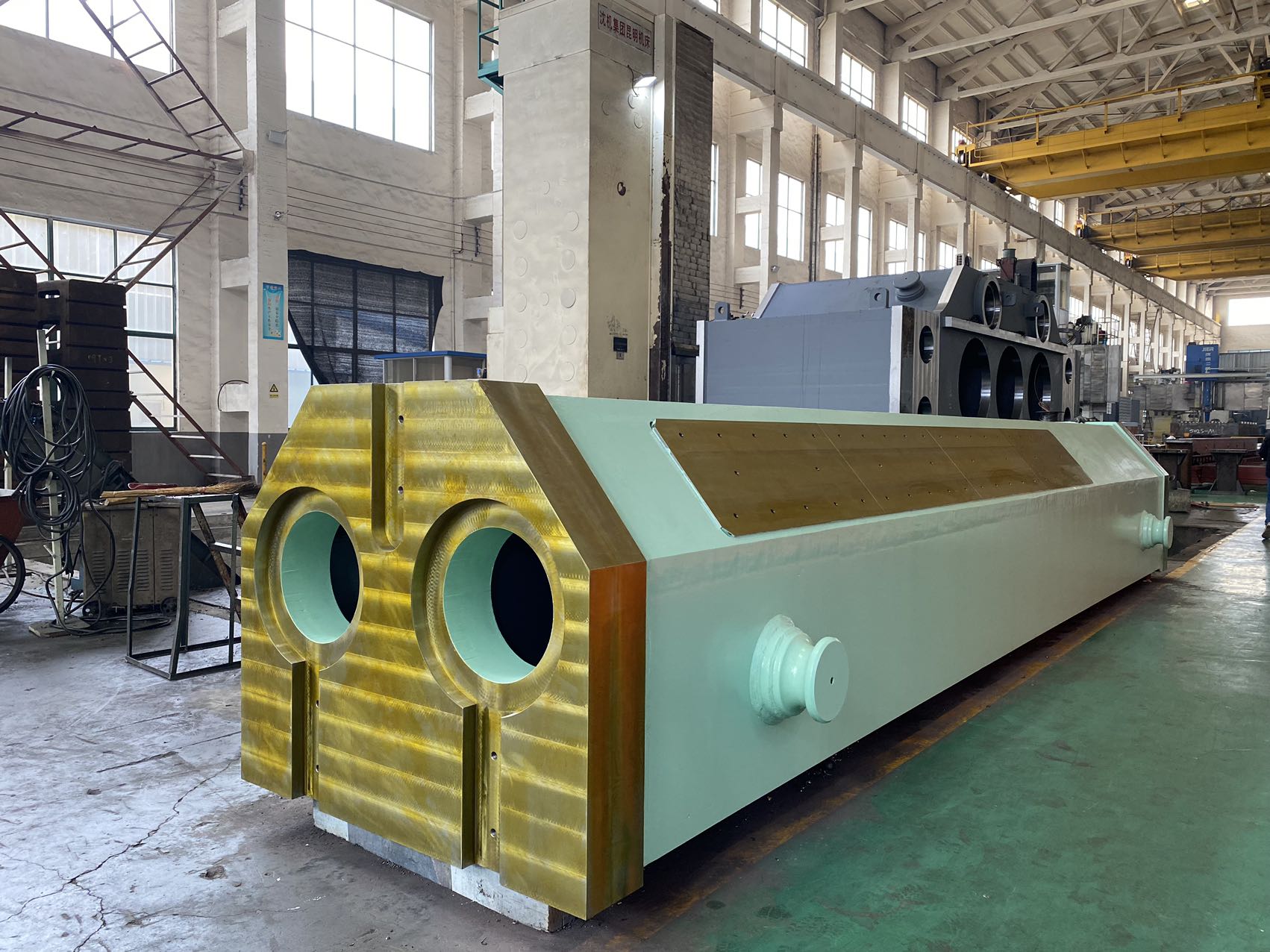

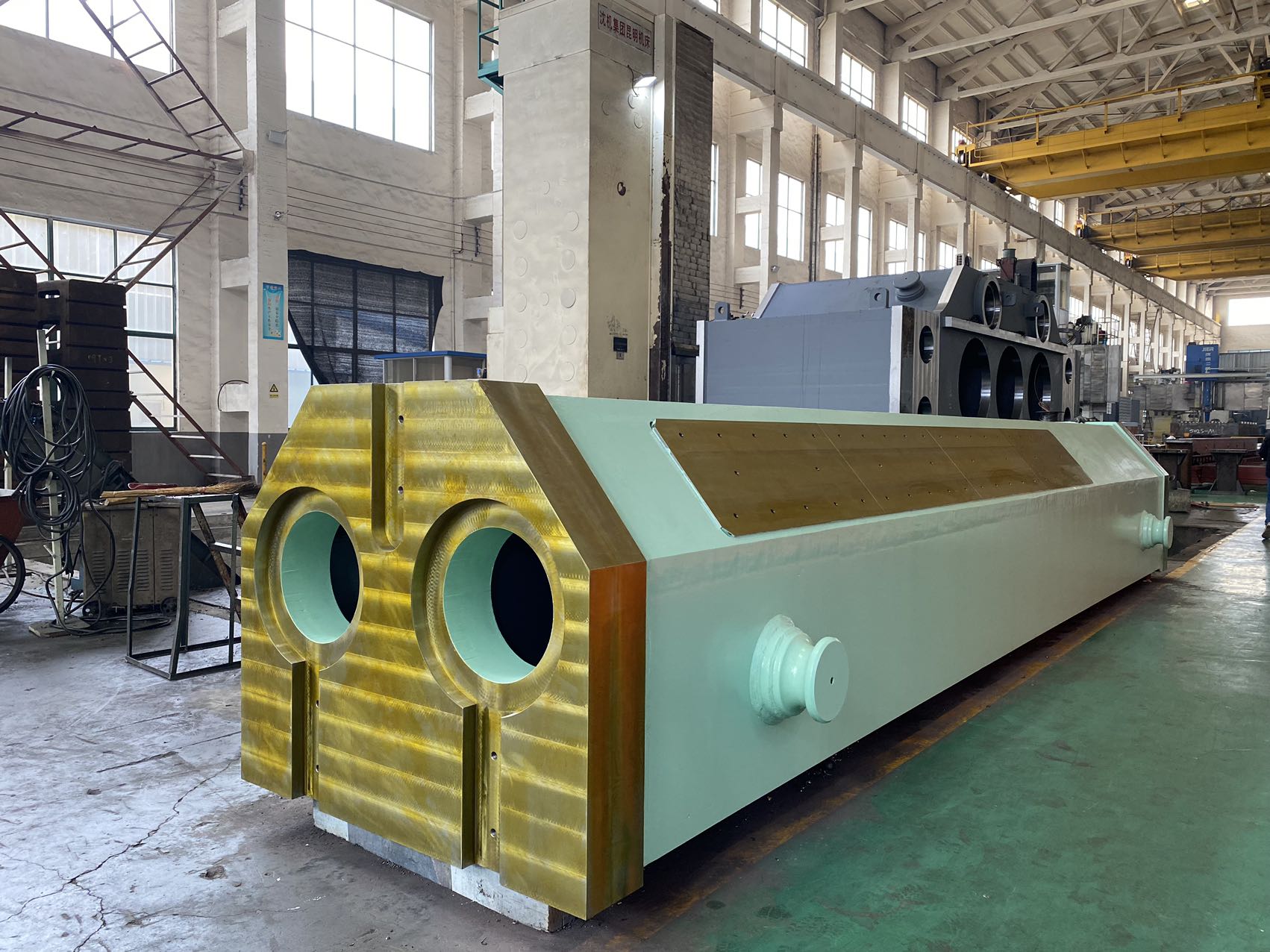

KUNFENG Steel is a one stop shop for all your fabrication needs. Our precision CNC metal machining services are designed to cater to your needs, whether you require a one-off prototype or low to full-volume production. Contact us to learn more!