-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

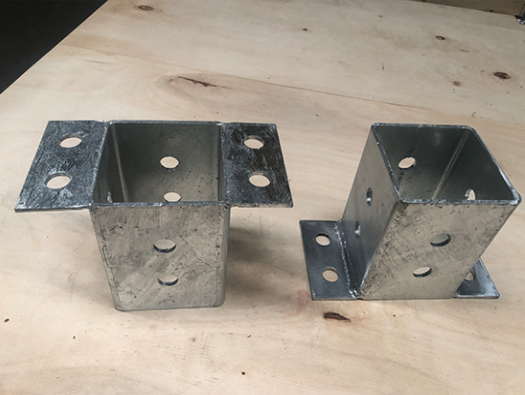

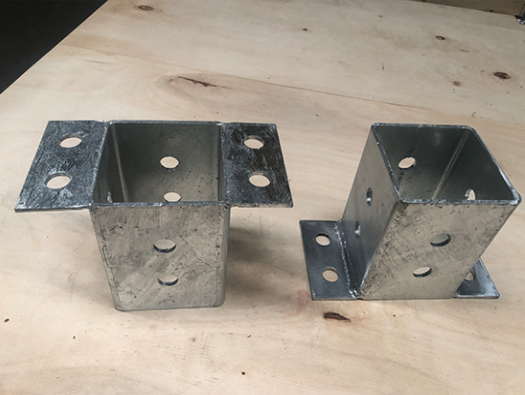

Galvanized square tube welding connectors refer to welded parts used to connect galvanized square tubes, usually made of galvanized steel.

Galvanized square tube welding connectors refer to welded parts used to connect galvanized square tubes, usually made of galvanized steel. These connectors include various types of elbows, tees, crosses, flanges, reducers, etc., which are used to connect, divert or change the flow direction of tubes in the tubeline system. These connectors are connected to galvanized square tubes by welding to ensure the sealing and stability of the piping system. These connectors are commonly used in piping systems in construction, industry, municipal engineering and other fields, and are corrosion-resistant, wear-resistant and durable.

● Cutting: Cut the galvanized square tube according to the design requirements, ensuring that the length and angle meet the requirements.

● Grinding: Grind the cut galvanized square tube to remove burrs and sharp edges to ensure welding quality.

● Welding: Use appropriate welding technology to weld the galvanized square tube connectors to the galvanized square tube to ensure firmness and reliability.

● Galvanizing: Galvanize the welded connections to improve their corrosion resistance and service life.

● Inspection: Conduct quality inspection on galvanized square tube welded connections to ensure compliance with relevant standards and design requirements.

Features:

● It is connected by welding process, which has high strength and stability, and can withstand large pressure and vibration.

● After galvanizing treatment, it has good corrosion resistance and can adapt to various harsh environments.

● The connectors are reasonably designed and easy to install, which can greatly improve construction efficiency.

● The connector has a simple structure and is easy to maintain, which can reduce later maintenance costs.

● Excellent corrosion resistance and welding technology ensure the long life of the connector.

Scenes to be used:

● Construction industry: used to connect various building components, such as beams, columns, slabs, etc., to improve the stability and durability of buildings.

● Equipment support: used to support and fix various equipment components to ensure the normal operation and service life of the equipment.

● Tube installation: used to connect various tubes, such as ventilation tubes, water tubes, etc., to ensure the sealing and stability of the tubes.

● Bridge engineering: used to connect various parts of the bridge to improve the load-bearing capacity and stability of the bridge.