-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

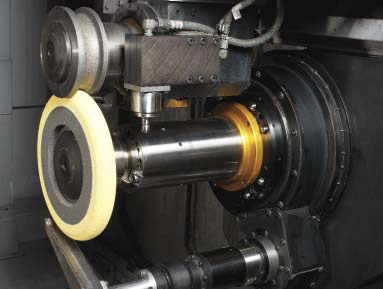

CNC grinding involves the removal of small amounts of metal using a high-speed abrasive rotating wheel as the cutting tool. The grinding wheel remains stationary, while the workpiece is fastened to the machine and moves in the X, Y, or Z-axis. The specific movements required depend on the part's shape and size, but typically involve multiple passes to achieve the desired finished dimensions.

Most Common Type of CNC grinding processes:

1. Surface Grinding: Surface grinding is a machining process that involves removing small amounts of material from a flat surface of a workpiece using an abrasive grinding wheel. This process can be used to achieve tight tolerances and high surface finish requirements on a wide range of materials.

2. Cylindrical Grinding: This process is commonly used to produce precision cylindrical parts with tight tolerances and high surface finish requirements.

3. Centerless Grinding: This process grinds cylindrical parts without the need for a centering mechanism, making it ideal for high-volume production.

4. Internal Grinding: This process grinds the inside diameter of a workpiece, typically to produce precision bores or holes.

5. Thread grinding: thread grinding is commonly used in the manufacturing of precision threaded components for various industries, including aerospace, automotive, and medical.

KUNFENG Steel offers a full range of grinding operations that can be optimized for the design and complexity of your custom components.

APPLICATIONS OF CNC GRINDING INCLUDE:

Aerospace: CNC Grinding is used to produce precision components for aircraft engines and landing gear, as well as other aerospace components that require tight tolerances and high surface finishes. Turbine rings and turbine shafts are two of the many aerospace components commonly precision ground.

Automotive: Grinding is used to produce engine components, transmission parts, and other precision components for automobiles.

Medical: Medical industry parts should be corrosion and wear-resistant to ensure that they are durable under the cleaning and sanitization methods they will face. Grinding is used to produce medical implants, surgical instruments, and other precision components for the medical industry.

Tool and Die: Metal rrinding is used to produce cutting tools, dies, and molds for a wide range of industries.

Electronics: CNC grinding is used to produce precision components for electronic devices such as computer hard drives and cell phone components.

KUNFENG Steel is your single-source provider for CNC grinding and supplies complete precision machining solutions. From the design and prototyping stage of your custom components to finishing them with CNC ground precision, KUNFENG Steel delivers versatile metalworking services with superior consistency and quality control in accordance with the latest ISO 9001:2015 standards.