-

Call Now ! +86 177 2978 0576

Call Now ! +86 177 2978 0576 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

Boring, drilling, and reaming are all machining processes that involve creating holes in a workpiece, but there are some key differences between them.

• Drilling is the process of creating a hole in a workpiece using a drill bit. The drill bit is rotated at high speed and pressed into the workpiece, removing material and creating a hole.

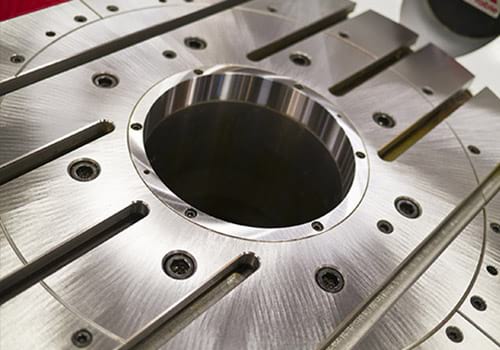

• Boring is a process that is similar to drilling, but it is typically used to enlarge an existing hole or create a hole that is not circular. Boring uses a single-point cutting tool that is fed into the workpiece, removing material and creating a hole that is larger than the original drilled hole.

• Reaming is a process that is used to improve the surface finish and accuracy of a drilled hole. Reaming uses a multi-point cutting tool called a reamer, which is rotated and fed into the workpiece. The reamer removes a small amount of material, improving the surface finish and accuracy of the hole.

The connection between these processes is that they are all used to create holes in a workpiece. Drilling is typically the first step, used to create a pilot hole. Boring is then used to enlarge the hole or create a hole that is not circular. Finally, reaming is used to improve the surface finish and accuracy of the hole.

Overall, while drilling, boring, and reaming are all related machining processes, they are used for different purposes and involve different tools and techniques. Understanding the differences between these processes is important for selecting the appropriate machining method for a given application.

KUNFENG Steel is proud of offer a host of steel machine service, including steel cutting and welding, CNC milling, boring, turning and threading, etc.

Visit our page to learn more about the size parts we can do for you.