-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

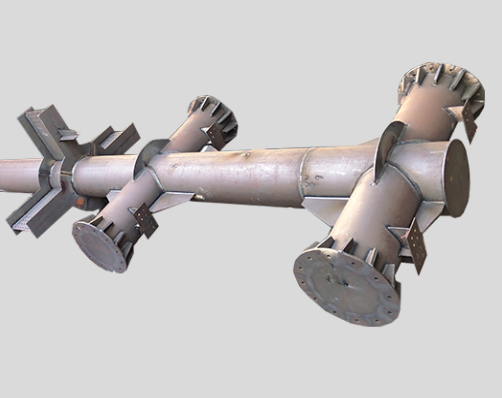

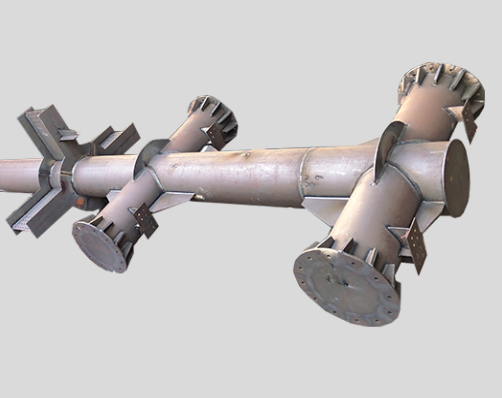

Large diameter welded round pipe column is a large-scale circular pipe made by welding process. Its diameter is usually larger and can meet various industrial and engineering needs.

Large diameter welded round pipe column is a large-scale circular pipe made by welding process. Its diameter is usually larger and can meet various industrial and engineering needs. Its diameter is usually above DN1000, and some can even reach several meters, with large load-bearing capacity and use space.

Manufacturing process:

● Steel plate cutting: Cut the steel plate into tube blanks of a certain length to ensure the length and verticality of the tube blanks.

● Edge processing: Process the edges of the tube blank to remove burrs, sharp edges, etc. to ensure welding quality.

● Pre-bending and sizing: Pre-bend and sizing the tube blank to make it round and ensure its roundness and verticality.

● Welding: Use automatic welding equipment or manual welding methods to weld the pipe blanks to form a circular pipe column.

● Non-destructive testing: Conduct non-destructive testing on the welded round pipe columns to check the quality of the welds and ensure their safety performance.

● Anti-corrosion treatment: Perform internal and external anti-corrosion treatment on the cylindrical column to extend its service life.

Features:

● Due to its larger diameter, it can withstand greater pressure and load and has better mechanical properties.

● It is made by steel plate cutting, welding and other processes. Compared with casting, forging and other processes, its production cost is lower.

● Internal and external anti-corrosion treatment can be used to effectively prevent erosion by corrosive media and improve its durability and service life.

● It can be customized according to customer needs. Round pipe columns with different specifications, materials and anti-corrosion requirements can meet different engineering needs.

Scenes to be used:

● Petrochemical industry: used to manufacture pipeline systems to transport various fluid media, such as oil, natural gas, chemical raw materials, etc. At the same time, due to its strong corrosion resistance and load-bearing capacity, it is often used to manufacture reactors, storage tanks and other equipment.

● Electric power industry: used in the manufacture of chimneys, thermal pipes and other equipment. Due to its good heat resistance and mechanical properties, it can withstand high temperatures and pressures.

● Water treatment industry: used to manufacture water treatment equipment, water pipelines and other facilities. Due to its strong corrosion resistance and load-bearing capacity, it can ensure the stability and safety of water quality.

● Construction industry: used to manufacture large structural parts, support frames and other facilities. Due to its large load-bearing capacity and stability, it can ensure the safety and stability of the building.