-

Call Now ! +86 13390692151

Call Now ! +86 13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

H-beam has wider flanges than I-beam, but I-beam has tapered edges. The width is the flange and the height is the web.

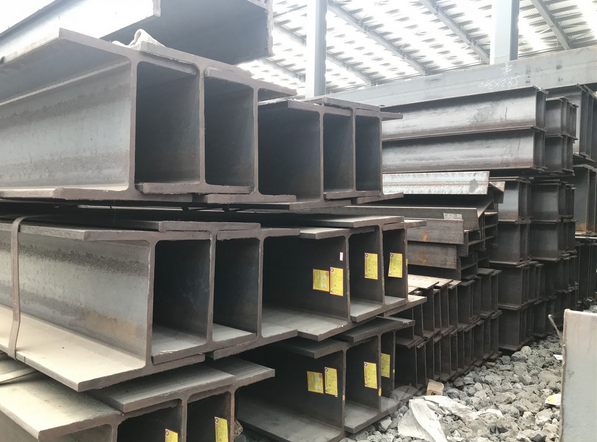

Steel Beams are widely used throughout the construction industry when supporting heavy loads is required. Commonly termed an “I” Beam because of its shape, beams provide great load bearing support when used horizontally or standing as columns. Available in two configurations, the most popular being the Wide Flange Steel Beam aka H Beam or W Beam with non-tapered flanges. This beam shape has a wider profile for added horizontal strength, making it ideal for sky scrapers or as a house beam, along with bridge beams, trailers, platforms, etc.

H-beam has wider flanges than I-beam, but I-beam has tapered edges. The width is the flange and the height is the web.

The difference between the H and I beams is the flange per band ratio. The H beam tends to be heavier than the I beam, which is why some say it is better than the I beam, but this is subjective, as the H beam is generally heavier.

The differences between I Beam and H Beam

Due to their slightly different cross-section shape, thicker central web and wider flanges, H beams can bear larger loads than I beams. While both are advantageous load-bearing structures, due to how long H beams can span for, they are more reliable for larger-scale projects. However, I beams are lighter and still have proven highly effective in numerous applications.

H beams application:

H-beams are widely used in the construction industry and are available in a variety of standard

sizes. H-beams may be used both as beams and as columns.