-

Call Now ! +86 13390692151

Call Now ! +86 13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

With the development of the automotive industry, high efficiency, high precision, and stable processing of complex components have become measures to reduce product production cycles and increase ente

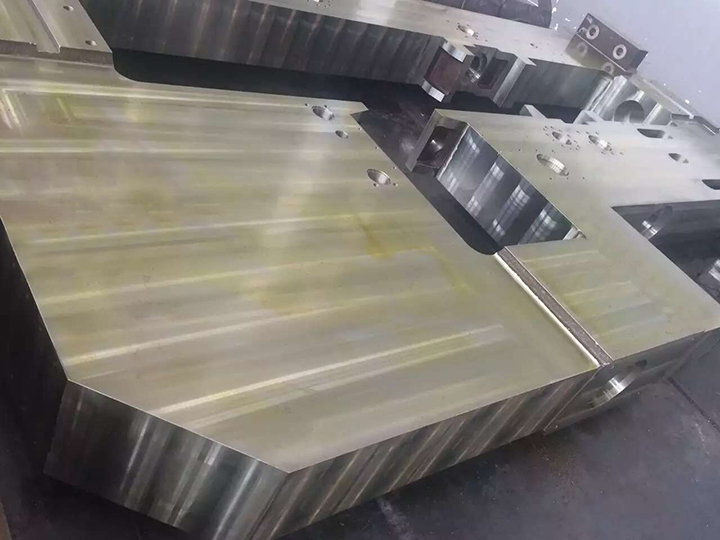

With the development of the automotive industry, high efficiency, high precision, and stable processing of complex components have become measures to reduce product production cycles and increase enterprise efficiency and competitiveness. CNC gantry milling machines are highly capable of producing complex automotive parts with ease. In modern automotive manufacturing, virtual manufacturing, flexible manufacturing, and integrated manufacturing have all been widely adopted in conjunction with CNC machining.

Compared with manual production, CNC gantry milling machines have laid the foundation for achieving standardization and standardization of automotive parts manufacturing, improving the production quality and actual equipment rate of domestic automobile parts.

Features of CNC gantry milling machine:

Features | Use |

High accuracy and precision | For complex geometry workpieces |

Automatic tool changing | High volume/bulk production of products |

Multiple tool option | For multiple machining operations in a single setup |

Chip Removal | Keeping the worktable and workpiece clean |

Coolant Management | Preventing tool or workpiece damage due to heat |

Multiple cutting axes/ orientation | For complex geometry workpieces |

Ergonomic and safe | For a simple and straightforward machining operation |

Automatic Pallet change | High volume/bulk production operations |

KUNFENG Steel has a gantry milling machine with machining size of 6 x 6 x 16m, and multiple gantry machining centers in various sizes. Apart from the above machines, CNC probe are available in KUNFENG Steel, which is an important device used to accurately measure the position and dimensions of a workpiece, tool, or fixture.