-

Call Now ! +86 177 2978 0576

Call Now ! +86 177 2978 0576 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

Introduction:

Proper maintenance of CNC machining centers is essential for maintaining their performance, accuracy, and longevity. Regular maintenance helps prevent unexpected breakdowns, reduces downtime, and ensures consistent production quality. In this article, we will discuss the maintenance methods for machining centers, including daily, weekly, monthly, semiannual, and annual maintenance tasks.

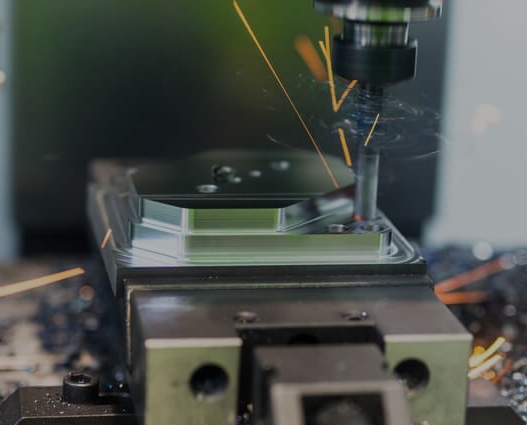

Daily Maintenance:

1. Cleanliness: Keep the machining center clean by removing chips, debris, and coolant residues from the lathe, spindle, table and pallet. Use an air gun or vacuum to clean the work area, tool holders, and chip conveyor. Wipe down the machine surfaces with a clean cloth.

2. Lubrication: Check and replenish lubrication levels as per the manufacturer's recommendations. Lubricate the guide rails, ball screws, and other moving parts as necessary.

3. Visual Inspection: Check that the liquid coolant and oil level is about 2/3 of the entire tubing. Inspect the machine for any signs of abnormal wear, loose connections, or damaged components. Pay attention to coolant leaks, unusual noises, or irregularities in tool performance.

4. Tool Inspection: Check the condition of cutting tools and change them if worn or damaged. Ensure the tool holders are clean and securely tightened.

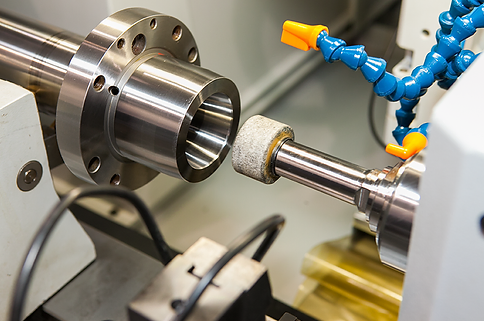

Weekly Maintenance:

1. Spindle Maintenance: Inspect the spindle for any signs of damage or wear. Clean the spindle taper and tool holders thoroughly. Apply a thin film of grease or anti-seize compound to the taper for protection against corrosion.

2. Coolant System: Clean the coolant tank and replace the coolant if necessary. Check for proper coolant flow and ensure filters are clean and functional. And set the oil cooler temperature at 26-28 degrees.

3. Axis Lubrication: Check the lubrication system for each axis and replenish the lubricant if needed. Verify smooth movement and proper lubrication to prevent excessive wear.

4. Electrical Components: Inspect electrical connections, cables, and wiring for any signs of wear or damage. Tighten loose connections and replace damaged cables or connectors.

Monthly Maintenance:

1. Spindle Runout Check: Measure the spindle runout using a dial indicator. If the runout exceeds the specified tolerance, contact the manufacturer for further inspection or repairs.

2. Axis Alignment: Verify the alignment of each axis using precision measurement tools. Adjust X, Y, Z axes as necessary to ensure accurate machining. In addition, check the rail axes in a smooth condition.

3. Ball Screw Inspection: Check the condition of the ball screws for wear or backlash. Clean and lubricate the ball screw assemblies according to the manufacturer's recommendations.

Semi Annual Maintenance:

1. Coolant System Maintenance: Clean and inspect the coolant system thoroughly. Flush the coolant lines, clean filters, and replace worn-out components. Ensure proper coolant flow and temperature control.

2. Lubrication System Maintenance: Clean and refill the lubrication system. Replace filters and purge air from the system. Follow manufacturer guidelines for lubricant selection and application. Disassemble the three-axis anti-chip shield, clean the three-axis tubing joint, ball guide screw, three-axis limit switch, and test whether it is normal. Check whether the effect of the hard rail scraping blade of each axis is good.

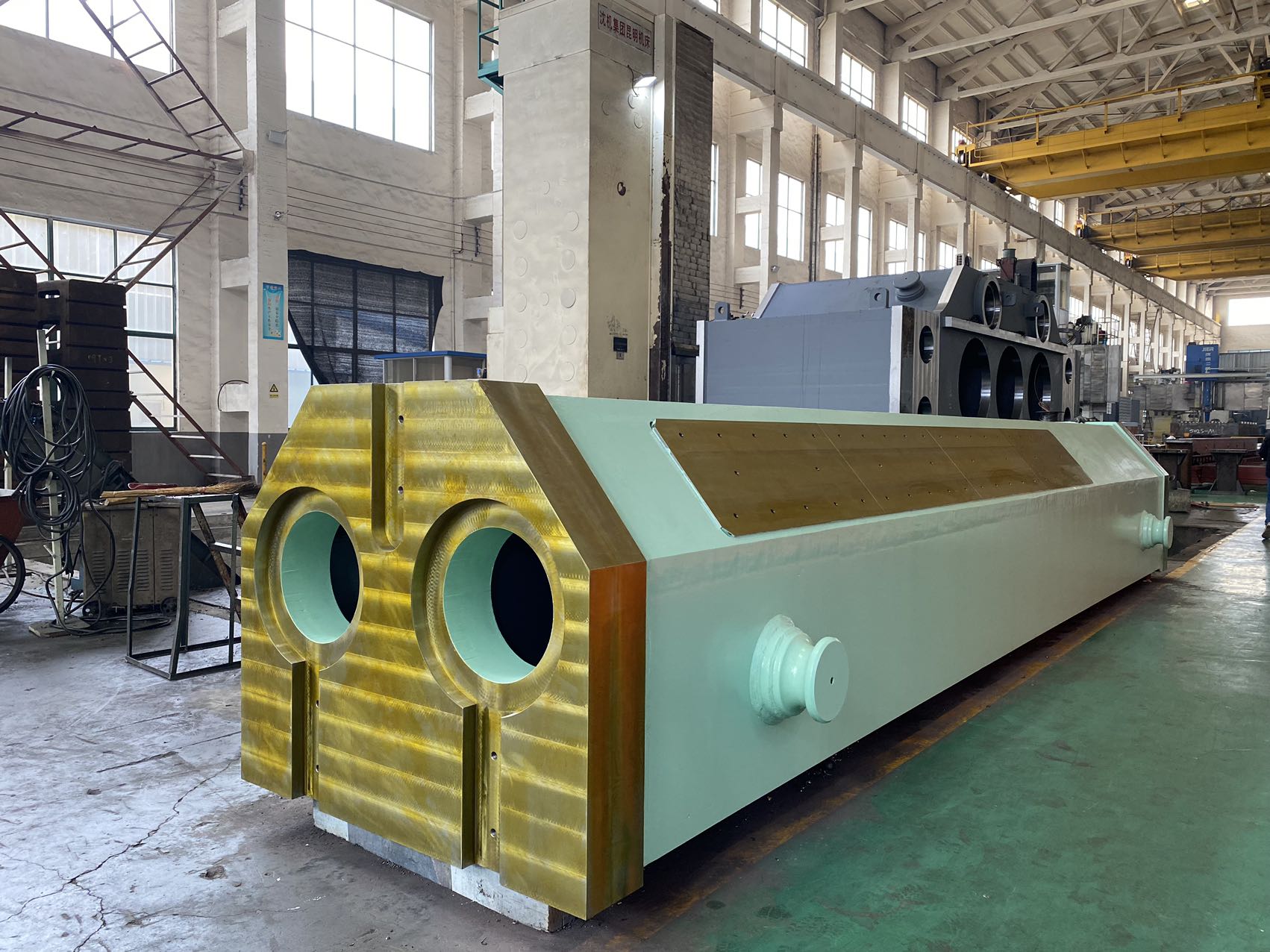

Machined Part for Marine Industry

Annual Maintenance:

1. Spindle Maintenance: Schedule a professional inspection and maintenance of the spindle unit. This may include bearing replacement, balancing, and other specialized procedures.

2. Axis Calibration: Perform a comprehensive calibration of all axes to ensure accurate positioning and movement. Consult the machine manual or manufacturer for specific calibration procedures.

3. Software and Control System Update: If applicable, update the machine's software and control system to the latest versions. This ensures compatibility with new features and enhances machine performance.

Conclusion:

Regular maintenance is crucial for the optimal performance and longevity of CNC machining centers. By following a comprehensive maintenance schedule that includes daily, weekly, monthly, semi annual, and annual tasks, manufacturers can minimize unplanned downtime, ensure consistent quality, and extend the lifespan of our machining centers. Always refer to the machine's quality and extend the lifespan of their machining centers. Always refer to the machine’s manual and consult with the manufacturer for specific maintenance guidelines and procedures.

With more than decade in the business, trust in KUNFENG Steel as your CNC machining and large part fabrication partner. Our staff is committed to surpassing your expectations by providing convenient, efficient, and cost-effective solutions for your next project. Contact us now to request a quote.