-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

Definition:Arc welding is a type of welding that uses an electric arc to melt and fuse metals together. It is one of the most common welding processes used in various industries, including constructio

Definition:

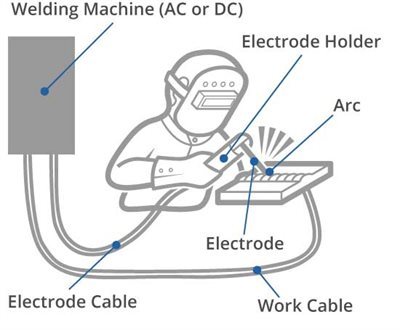

Arc welding is a type of welding that uses an electric arc to melt and fuse metals together. It is one of the most common welding processes used in various industries, including construction, manufacturing, and repair.

The basic principle of arc welding is to create an electrical current between an electrode and the metal being welded. When the electrode is brought into contact with the metal, an electric arc is created, which generates intense heat that melts the metal. As the metal melts, the electrode is slowly move along the joint to create a weld pool. The heat from the arc melts the metal, and as the metal cools and solidifies, it fuses the two pieces of metal together.

Arc welding can be applied to weld parts of various shapes and sizes, from thin sheets of metal to thick sections of structural steel. The process is commonly used to join two or more pieces of metal together, such as in the construction of buildings and bridges, or in the manufacturing of machinery and equipment. When combined with CNC machining, it becomes possible to manufacture finer parts that are used in industries such as pharmaceuticals, aerospace, and molds.

Welding line

Overall, arc welding is a versatile and widely-used welding process that is essential for a variety of industries. With the proper equipment and training, skilled welders can produce strong, reliable welds that can withstand even the most demanding applications.

KUNFENG Steel provide custom solutions for various industries. Apart from CNC milling, drilling, boring, roaming, steel cutting and welding can be supplied. Contact us to let our technician help.