-

Call Now ! +86 177 2978 0576

Call Now ! +86 177 2978 0576 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

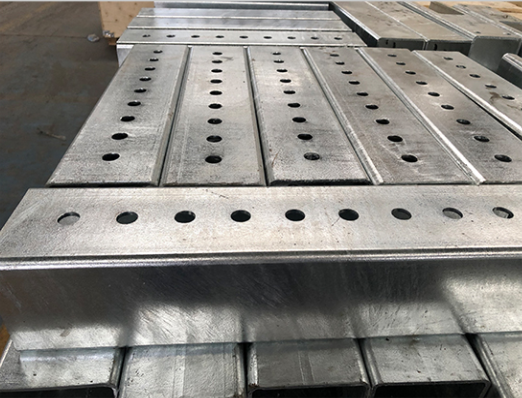

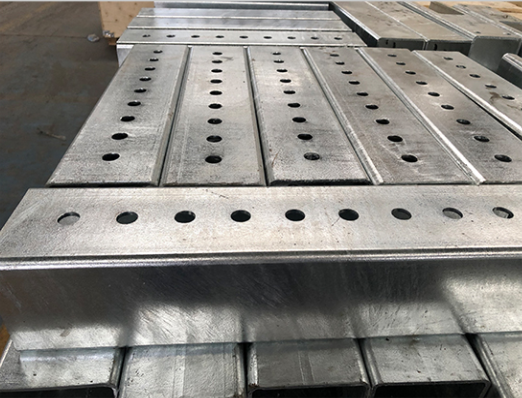

Laser drilling of square tubes is an advanced processing method that uses high-energy laser beams to irradiate the surface of metal square tubes to quickly melt, vaporize or reach the ignition point.

Laser drilling of square tubes is an advanced processing method that uses high-energy laser beams to irradiate the surface of metal square tubes to quickly melt, vaporize or reach the ignition point. At the same time, high-speed airflow blows away the splashing, melting or burning materials. This enables drilling. Compared with traditional mechanical drilling, laser drilling has higher processing accuracy and faster processing speed, and does not cause problems such as tool wear and coolant usage. Therefore, laser drilling is widely used in many industries.

Operational requirements:

● Equipment requirements: Equipment for laser drilling of square tubes must have the characteristics of high precision, high speed and high stability. The power and spot diameter of the equipment need to be selected according to actual processing needs. At the same time, the operation and control accuracy of the equipment also need to meet the processing requirements.

● Operator requirements: Operators must undergo professional training and assessment, and have relevant theoretical knowledge and practical experience. Operators should be able to use the equipment skillfully and adjust equipment parameters and process parameters according to different processing needs.

● Process requirements: Before laser drilling of square tubes, the material, thickness, surface quality, etc. of the square tubes should be inspected, and a reasonable process plan should be formulated according to the processing requirements. The process plan should include the settings of laser power, scanning speed, pulse frequency and other parameters, as well as cooling and protective measures during the processing.

Features:

● Laser drilling is highly precise and can precisely control the size, shape and depth of the drilled hole. For high-precision processing requirements, such as micro holes, narrow slits, etc., laser drilling has significant advantages.

● The processing speed of laser drilling is very fast and can quickly penetrate the surface of square tubes to achieve efficient production. Compared with traditional mechanical drilling, laser drilling can greatly shorten the processing cycle and improve production efficiency.

● The equipment has a high degree of automation, which can reduce manual operations and human errors and improve the consistency and stability of processing. At the same time, automated equipment can greatly reduce problems such as workers’ labor intensity and harsh working environment.

● It can be applied to the processing of square tubes of various materials, such as stainless steel, aluminum alloy, copper alloy, etc. At the same time, laser drilling can also achieve high-quality processing for square tubes of different thicknesses.

● No harmful substances and waste are produced during laser drilling, making it an environmentally friendly processing method. In addition, laser drilling consumes less energy and can reduce production costs for enterprises.

Manufacturing processes:

● Preparation work: Before laser drilling of square tubes, the square tubes should be cleaned and dried to ensure the quality and stability of the processing. At the same time, operators should inspect and debug the equipment to ensure normal operation of the equipment.

● Parameter setting: Based on processing requirements and factors such as the material and thickness of the square tube, the operator needs to set reasonable laser power, scanning speed, pulse frequency and other parameters. In addition, it is necessary to select appropriate parameters such as spot diameter and focus position to ensure the quality and efficiency of processing.

● Processing operation: Place the square tube on the workbench of the equipment and adjust the position to align it with the laser head. Start the equipment, input the set parameters into the control system, and start laser drilling. During the processing, operators should monitor the operating status and processing quality of the equipment at any time. If there are any abnormalities, they should promptly adjust parameters or stop processing.

● Quality inspection: After the processing is completed, the square tube should be inspected for quality, including inspection of hole diameter, hole depth, surface quality and other indicators. If there are any unqualified products, they should be reworked or scrapped in time.