-

Call Now ! 0086-13390692151

Call Now ! 0086-13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

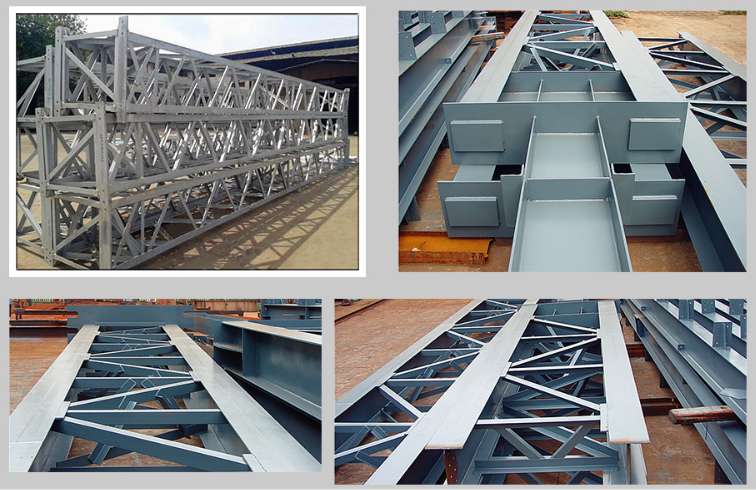

Steel lattice columns are a supporting element used in building structures, usually made of steel. Its main function is to bear and transmit the load of the building to ensure the stability and safety of the building structure.

Steel lattice columns are a supporting element used in building structures, usually made of steel. Its main function is to bear and transmit the load of the building to ensure the stability and safety of the building structure.

Steel lattice columns typically have hollow square or circular cross-sections, a design that reduces weight while maintaining sufficient strength. They are usually fixed to the foundation and connected with other structural elements such as steel beams, floor slabs, etc. to form the frame structure of the entire building.

In some industrial and commercial buildings, steel lattice columns are often used to construct large-span and high-load-bearing buildings because steel has high strength and durability and can meet these special requirements. In modern architecture, steel lattice columns have become a common structural element. Their design and manufacturing have undergone precise calculations and engineering techniques to ensure that they play the best supporting role in the building structure.

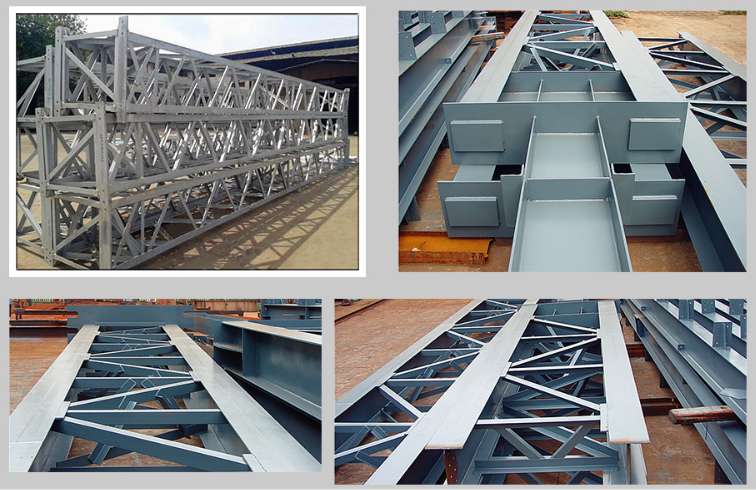

Processing technology:

1. Cutting: According to the design requirements, use CNC machine tools or manual cutting to cut the steel into the required shape and size.

2. Straightening: Straightening and flattening the cut steel to ensure processing quality and stability.

3. Processing grooves: Processing grooves in the parts that need to be welded to ensure welding quality and joint stability.

4. Drilling: According to the design requirements, use a drilling machine or CNC machine tool to drill to ensure the position and size accuracy of the hole.

5. Inspection: Inspect the processed steel lattice columns, including dimensional accuracy, shape accuracy, groove quality, etc., to ensure that they meet the design requirements.

Welding process:

1. Preparation before welding: Clean the weld, remove oxide scale and rust in the groove, and prepare welding materials and protective gas.

2. Positioning welding: Positioning welding is performed at the appropriate position of the steel lattice column to ensure the position and stability of the steel lattice column.

3. Welding: Use appropriate welding methods and process parameters for welding to ensure welding quality and joint stability.

4. Post-welding treatment: Post-weld treatment is performed on the welded steel lattice columns, including cleaning welding slag, trimming appearance, stress relief, etc., to ensure compliance with design requirements.